May Flowers Start with April Showers

April 18 2016

Oh, it’s spring again and everyone is so happy and joyful. May is almost here, the April showers cleanse all things of the salt and gloom of winter and fall. During spring, everyone is itching to go outside and feel the sunshine on their faces. Windows are open, houses are being cleaned out, and garage sale signs are on every corner. Lakes and rivers are calling, and grills are begging for charcoal. Do you think your company experiences spring like this?

The answer to that question is yes. The next question is what do you do about it? You can’t just let everyone off early on Friday’s because it is spring, but you can do things that will help your company be ready to engage in the season. You can have your own personal April showers. No, I don’t think you should power wash the employees or the warehouse, but there are some things you can do to get ready for the year.

1. Open the doors to your freight docks and let a cross breeze fill up the space. I swear that through the winter months, dust and artificial light has an effect on people. Use the nice weather as an opportunity to seize some fresh air. Your employees will thank you for it. Unless you have temperature sensitive items in your warehouse, this is a great way to just open up and let the warehouse air out.

Once the doors are open and the dust particles are clearly visible in the air, it’s time to clean. Just like at home your warehouse needs a good shake out. This is the time to sweep EVERYTHING, start at the top rack and dust the boxes and pallets. You will be surprised at what is “living” on your overstock racks.

2. Double check stock rotation while you are up there. If you are marking your stock when it comes in… Wait, are you doing that? Having inventory that is non-perishable might make stock rotation less of an “issue” but perishable or not, this is an issue. Do not let the idea that your merchandise doesn’t expire, like food, cosmetics or landscaping materials, keep you from stock rotation. Your stock does expire, with customer demand change, outmoded parts, and new product lines.

A great idea for stock rotation is to mark every shipment in January with a white sticker. Better yet, you can get the stickers printed with a number to symbolize the year the items came in. If every month had a colour and every sticker had a year on it, climbing to the top of your pallet racks for stock rotation checks is simple and easy. Even the new guy can do it. This is the best part, it’s is not rocket science, and even if your new guy or gal is a rocket scientist, after a warehouse of stock checking they will be thankful for the no-brainer idea!

You might be saying, “But Danah, we get everything in pallets and it’s not practical to break down pallets to mark each box.” I say you’re right, but if you place a sticker on the front of the pallet with the correct colour and year, and a sheet of unused stickers to be put on the boxes as they are unpacked on top or in a clear envelope, the boxes can be marked as they are emptied off the pallet in the future.

Stock rotation is one of my biggest pet peeves. Should be yours to. First In First Out, oh, FIFO… so annoying to your pullers and packers. New boxes are so pretty! Just when you least expect it, your manufacturers outmode one of your product’s codes, names, packaging, case size, or something equally as annoying and subtle. You, my friend, will be stuck trying to decide what to do with the leftovers and scrambling to stop your people from putting the “pretty packaging” in shipping boxes instead of the FIFO style required. This battle can be easily won with a sticker. A sticker that costs less than a penny and takes less labour dollars than two pennies to adhere can save you thousands down the road.

3. Clean up your shipping and receiving areas once your stock is marked and rotated. These areas are natural collection areas for junk, trash and other weird and strange stuff. Ever wonder where the packing slip went for that one order that was critical, and the driver was waiting on you, and your people wanted to go home, and you were about to pull your hair out? I know where it is! Look under that workstation in the furthest area, behind a dust bunny three inches from one corner being in view with 14 partial foot prints, the guy who said he never saw its signature, and a coffee stain… Yeah, it’s there. This happens to all of us, and as frustrating as it is to have found it four months later, that is why we do spring clean-up.

If you can, move workstations, temporarily uproot printers and tape machines. Get out the disinfectant and kill all the winter germs and throw out the clutter. Speaking of tape machines, they get gross and gummy. Open them up, wipe them out. The time your people will waste trying to fix a machine that isn’t working is heinous. Fixing a tape machine or printer will take four people and an internet search before any headway is made.

Don’t take the chance, keep your equipment working with minimal lost labour dollars. Think of it this way, no one wants to clean it, but everyone wants to fix it. Throw away every single pen that doesn’t work (you can buy more; I promise). Clean the forklifts and wipe down the computer screens. Even if your computers are not touch screen, they are gross, I promise. If you have floors that can be cleaned by a professional Zamboni type machine, then rent it. I had a boss do that once and it made all the difference in the world.

Spring cleaning is the time to change all your lightbulbs to LED (at least change the ones that are out or flickering… you just looked up at one didn’t you?). There are cobwebs in the corners and air filters to change. Forklifts to printers, they are all in need of a good can of air, gears oiled, and a wipe down, especially the cup holders… yikes!

Once this is done you can look at your warehouse with pride, stand back, take a deep breath, and see all the sticker colours on the boxes like May flowers, the fruit of your labour. Consider doing this every quarter, not just in the spring. Check your stock rotation, make sure you are on the right track, and save a ton of energy, labour dollars and arguments over who really fixed the printer that eats all the orders. You will thank me later. As always I am here to help and enjoy all the comments and ideas that come in, so keep sending them my way!

Danah Head is an Executive Advisor for The Distribution Team. Danah has earned both her MBA in Technology Management for Supply Chain and MAED in Adult Education and Corporate Training. While pursuing her education, she worked in different purchasing and supply chain roles within the manufacturing industry. She has real world experience and technical training to help find the best solutions for warehouse and distribution companies. For more information, call (918) 992-5022 in Tulsa, Oklahoma or e-mail Danah@Distributionteam.com. Also be sure to visit The Distribution Team online www.thedistributionteam.com. Now: @Distribution_Tm on Twitter.

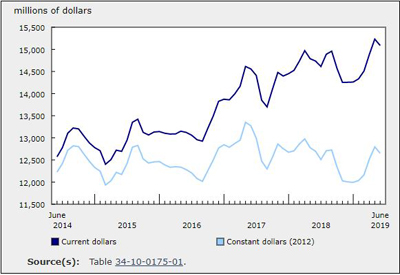

Loss, Theft, Damage… What is the Cost?

Customers = Profitability… Right?